2026 Best Practices in Chemical Manufacturing for Sustainable Growth?

In the evolving landscape of chemical manufacturing, sustainable growth remains a critical goal. Experts in the industry recognize that best practices are essential. Dr. Sarah Jensen, a leader in chemical innovation, states, "Sustainable practices in chemical manufacturing are not just an option—they're a necessity for future success." This sentiment resonates deeply as companies aim to balance productivity and environmental responsibility.

Current challenges in the sector are evident. Compliance with regulations can be burdensome, and adapting to market demands requires agility. Chemical manufacturers often grapple with the pressure of reducing emissions and waste. Yet, many struggle to implement effective strategies. There's a learning curve involved in adopting green technologies.

Despite these obstacles, opportunities abound. Sustainable growth can lead to increased efficiency and reduced costs. The integration of advanced technologies will redefine traditional processes. The path forward may not be seamless, but it holds promise for those willing to reflect and adapt. As we explore best practices in chemical manufacturing, the journey towards sustainability becomes increasingly vital.

Overview of Sustainable Practices in Chemical Manufacturing

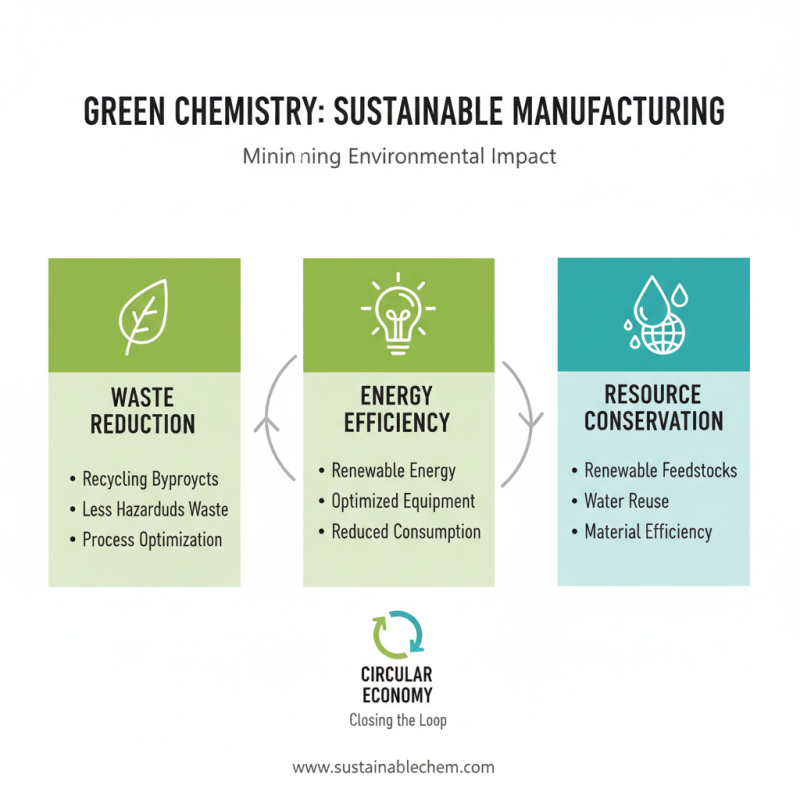

Sustainable practices in chemical manufacturing are more critical than ever. Companies are reevaluating their processes to minimize environmental impact. These practices include waste reduction, energy efficiency, and resource conservation.

Implementing closed-loop systems can significantly lower waste. This approach recycles raw materials back into the production process. For instance, using by-products as feedstock can reduce the need for new resources. However, many companies struggle with initial costs and technological challenges when adopting such systems.

Renewable energy sources play a vital role in sustainability. Solar and wind power can offset traditional energy usage. Still, transitioning to renewable energy requires planning and investment. Some facilities have found it difficult to justify the upfront expenses. Finding the right balance between innovation and cost is an ongoing challenge in the industry.

Key Technologies Driving Sustainability in Chemical Production

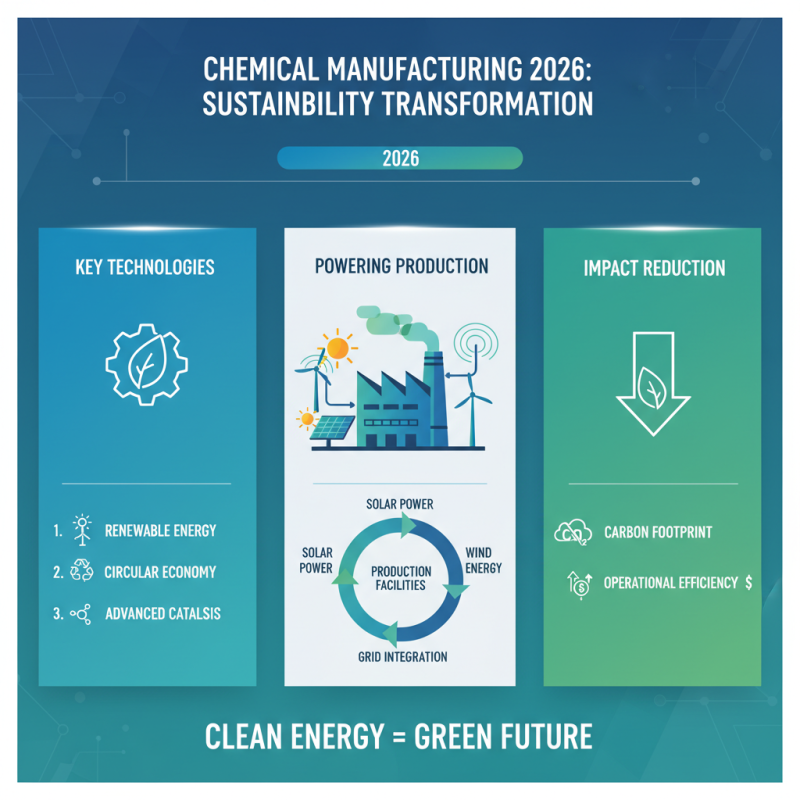

In 2026, the chemical manufacturing landscape is undergoing significant transformation. Key technologies are vital for driving sustainability. One such technology is the use of renewable energy sources. Solar and wind energy can power production facilities efficiently. By integrating these energies, manufacturers can dramatically reduce their carbon footprint.

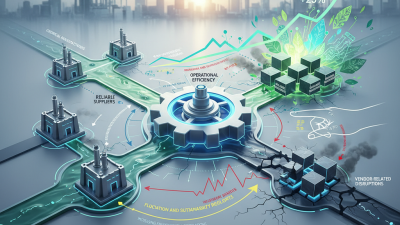

Another critical technology is process optimization. Advanced analytics and artificial intelligence are reshaping production lines. They help in minimizing waste and enhancing efficiency. However, the challenge lies in implementing these technologies across different scales of operations. Smaller manufacturers often struggle to invest in such innovations.

Biotechnology also plays a pivotal role. It allows for the development of eco-friendly materials. Yet, relying solely on biotechnological solutions can be short-sighted. Ensuring a balance between traditional methods and newer approaches can be complex. Companies must continuously evaluate their strategies to foster sustainable growth. Balancing innovation with practicality remains an ongoing challenge in the industry.

Regulatory Frameworks Impacting Sustainable Chemical Manufacturing

Sustainable chemical manufacturing is increasingly shaped by regulatory frameworks. These rules often dictate how companies operate. Compliance is crucial for staying in business. Yet, many firms struggle to keep up. Regulations can be complex and change frequently. Adapting to them requires resources many smaller companies lack.

Governments are emphasizing sustainability more than ever. Policies increasingly target reduced emissions and waste management. These shifts can pressure manufacturers. Some may feel overwhelmed, while others find opportunities. Those who invest in green technologies benefit in the long run. However, not all companies know how to transition effectively.

Moreover, regulations differ globally. What works in one region may fail in another. Companies must navigate these waters carefully. Building strong relationships with regulators is vital. Transparency can foster collaboration. Many businesses still hide behind compliance gaps. It's essential to confront these areas for improvement. As the chemical industry evolves, so too must our approaches to regulation and sustainability.

2026 Best Practices in Chemical Manufacturing for Sustainable Growth

This chart illustrates the impact of various best practices in chemical manufacturing on sustainability metrics for the year 2026. The practices include investment in renewable energy, waste reduction techniques, water conservation measures, and compliance with regulatory frameworks.

Case Studies of Successful Sustainable Strategies in Chemical Industry

Sustainable growth in chemical manufacturing is a pressing need. Many companies are adopting innovative strategies. This blog focuses on case studies that showcase successful sustainable practices.

One notable approach involves waste repurposing. A company transformed by-products into valuable raw materials. This not only reduced waste but also cut costs. Another instance is utilizing renewable energy sources. Firms shifted to solar and wind power. The switch lowered their carbon footprint significantly.

Tips: Start small. Evaluate your waste streams. Identify which by-products can be reused. Monitor energy consumption closely. Consider exploring alternative sources.

Sustainability is not without its challenges. Some companies struggled to change their existing processes. Resistance was common. Moreover, the initial investment often felt daunting. However, those who persevered noted long-term benefits. Economic and environmental gains are now intertwined.

2026 Best Practices in Chemical Manufacturing for Sustainable Growth

| Strategy | Description | Impact | Implementation Year |

|---|---|---|---|

| Green Chemistry Principles | Adoption of environmentally friendly processes and materials to minimize hazardous waste. | Reduced waste by 30% and increased safety in production. | 2023 |

| Circular Economy Practices | Implementing systems to recycle waste products back into production. | Increased resource efficiency, leading to a 25% reduction in raw material usage. | 2024 |

| Energy Efficiency Optimization | Upgrading equipment and processes to lower energy consumption. | Cut energy costs by 20% and reduced greenhouse gas emissions. | 2025 |

| Sustainable Supply Chain Management | Collaborating with suppliers to ensure sustainable sourcing of materials. | Improved product lifecycle sustainability and enhanced brand reputation. | 2023 |

| Digital Transformation | Utilizing IoT and AI to optimize operations and track sustainability metrics. | Increased operational efficiency by 15% and improved sustainability reporting. | 2026 |

Future Trends in Chemical Manufacturing for Sustainable Growth

The future of chemical manufacturing will depend heavily on sustainable practices. Innovations in energy efficiency are on the rise. Companies are exploring renewable energy sources, transitioning from traditional fossil fuels. Solar panels and wind turbines are becoming common sights in chemical facilities. This shift aims to lower emissions and production costs simultaneously.

Another trend is the use of biodegradable materials. Bioplastics are gaining traction, replacing conventional plastics. However, not every alternative is perfect. Some biodegradable materials still face challenges in recycling processes. The industry must improve infrastructure to handle these new materials effectively. This adaptation requires time and collaboration across sectors.

Investing in digital technology is also essential for growth. Smart sensors and AI can optimize operations, reducing waste. Yet, there is a risk of technology dependence. Not all companies can afford these innovations, potentially widening the gap in the industry. It's crucial to address these inequalities as we move toward a more sustainable future.

Related Posts

-

2025 Top 5 Specialty Chemicals for Sustainable Industry Innovations

-

Why Choosing the Right Chemical Vendors is Crucial for Your Business Success

-

How to Choose the Best Chemical Vendors for Your Business Needs

-

How to Find the Right Chemical Consultant for Your Business?

-

Top 10 Specialty Chemicals That Transform Industries and Boost Innovation

-

Top 10 Essential Features Every Chemical Lab Should Have